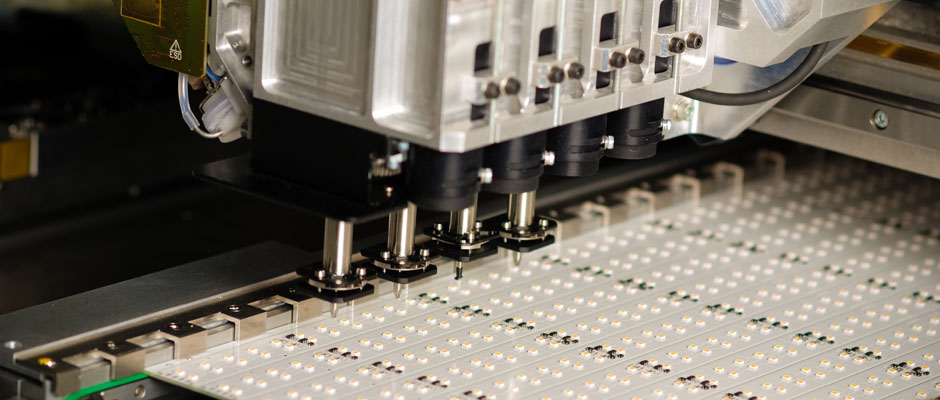

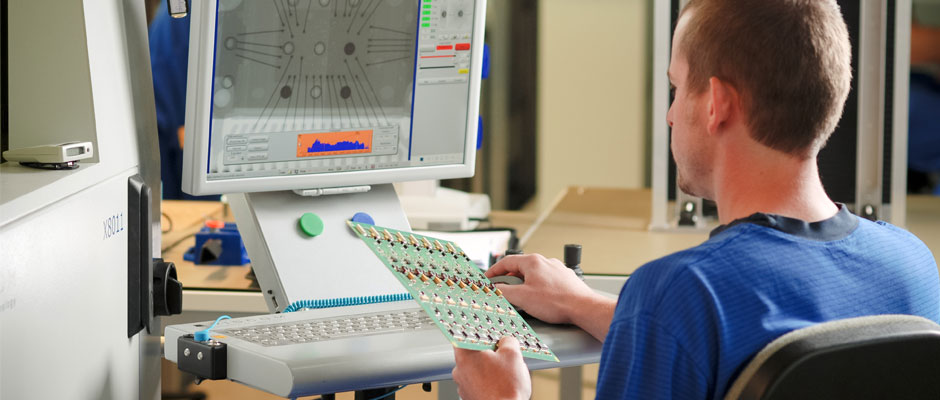

The latest equipment is the basis for our highly-automated production. Seitec produces your product from a line of samples to short batch series and large-scale productions with four SMD lines. The lines are characterised by their high flexibility and equipping. This reduces the developmental period of each product and results in short processing times. We are therefore able to produce sample boards in a really short time. Two AOI and an x-ray machine are used for the process assurance. The product planning and guidance is being done with the help of software solutions which are tailored to our needs.

SMD line 1:

– screen printer Ekra X4

– automatic loader Mimot Advantage

SMD line 2:

– screen printer Ekra X4 Base

– automatic loader Mimot MB300

– reflow oven SMT QP M

SMD line 3:

– screen printer Serio 4000

– SPI KOHYOUNG KY8030-2

– automatic loader Mimot 2x MB300

– reflow oven SMT QP L

SMD line 4:

– screen printer Serio 4000 multistep

– SPI KOHYOUNG KY8030-2 XL (to 1,5m circuit board)

– automatic loader 2x ASM Siplace SX

– reflow oven SMT QP L Plus

– AOI KOHYOUNG Zenith Advanced 3D XL

process monitoring and assurance:

– AOI Viscom S3088-III

– x-ray machine Viscom X8011